Kyoda Distillery. What defines the challenging yet practical whisky-making approach unique to Okinawa’s comprehensive beverage manufacturer, which produces Rum, Beer, Awamori, and Whisky?

A historic company that began with rum production.

Sugarcane, an important and abundant resource in Okinawa.

After the war, under American administration, Rum—more familiar globally—proved more accessible to foreigners than traditional awamori. It also gained popularity as a unique souvenir for tourists.

Against this backdrop, Helios Shuzo began its journey in earnest with rum production.

Its history of expanding its range of spirits in response to the times and market trends, while utilizing Okinawa’s climate and raw materials, has led to its current status as a comprehensive alcoholic beverage manufacturer.

The Challenge of Whisky Production: A Legacy Continuing Since 1963

Helios Shuzo began its whisky production in 1963.

It was a highly advanced endeavor for the time, driven by a clear vision: “To create a spirit from Okinawa that connects to the world.”

During this period, the company name changed from “Taiyo Jozō” to “Helios,” named after the sun god from Greek mythology.

The company aspired to be a bright light for people, blessed by the sun of the southern land of Okinawa.

This name, imbued with that aspiration, perfectly symbolizes the company’s founding principle: “Sake brewing that walks alongside the sun.”

Some of the stills, tanks, and mashing equipment currently used at the Kyoda Distillery were repurposed from equipment previously used in awamori and beer production.

This reflects the rationality unique to a comprehensive beverage manufacturer, combined with the ingenuity born on the production floor.

Raw Materials and Equipment Management

For whisky production, both unpeated malt and heavily peated malt are used.

The malt is not limited to Scottish sources; we also incorporate malt from New Zealand and Australia.

The range of expressions is broad, from peated types emphasizing impactful smokiness to unpeated types with long-lasting finishes, all designed with Okinawa’s aging environment in mind.

Batch size is 1 ton per batch.

There was also brown sugar for rum production

Saccharification and Fermentation

The saccharification and fermentation processes are carried out in the building dedicated to craft beer production.

Whisky and beer use different raw materials like malt and yeast, but their processes are very similar up to a certain point, allowing them to be brewed using the same equipment.

The expertise in temperature management and fermentation control cultivated through beer brewing is also applied to whisky mash production. This demonstrates the technical strength unique to a comprehensive beverage manufacturer. The whisky mash undergoes thorough lactic acid fermentation over a fermentation period of about five days.

The mash tuns and fermentation tanks are reportedly made by domestic manufacturers, and the pot stills mentioned later are also domestically produced.

Distillation Process

Three copper stills, identical in shape and size, are used for distillation.

These pot stills were originally used not only for whisky but also for distilling Awamori.

The still shape is quite unique

The line arm is horizontal

A rare combination where all sizes, head shapes, and line arm configurations are identical.

Kyoda Distillery is the only distillery in Japan distilling awamori using copper stills.

This stems from their original focus on barrel-aging awamori. They recognized that barrels are more suitable for long-term storage compared to traditional clay jars. Furthermore, they discovered that the clean base spirit produced by copper stills, free of off-flavors, is well-suited for barrel aging.

This accumulation of experimental decisions underpins the whisky production at the current Kyoda Distillery.

When producing whisky, the initial distillation is performed in the two rear stills, followed by redistillation of the first distillate twice in the front redistillation still.

Rather than using temperature control and modern equipment to produce a base spirit identical to that made on the mainland, the distillery deeply understands and embraces the traditional local environment of Okinawa, a southern island, and reflects this in the character of the spirit.

Kyoda Distillery’s whisky is born from facing this land head-on.

The 7-meter-tall storage tank was previously used for awamori

As a side note, the first distillate of whisky, shochu, and awamori all contain a fatty substance known as “fusel oil.”

This is an alcohol-derived component; in awamori, it is valued for its umami and richness.

Many distilleries separate the first distillate into three stages: heads, hearts, and tails.

The head also contains many impurities, such as the oils mentioned earlier, which are typically removed.

However, Kyoda Distillery , driven not only by a pursuit of pure quality but also by deep expertise in awamori, incorporates these oils to complete its first distillate.

However, if this initial distillate is left for too long, the oils can oxidize upon contact with air, potentially imparting a heavy or unpleasant aroma.

Therefore, at Kyoda Distillery, they proceed immediately to redistillation before such oily aromas develop.

The first distillate retains a high amount of oil

This technical judgment, honed through years of crafting both awamori and whisky, is a hallmark of Okinawan flavor.

Aging Process

The Kyoda Distillery has two aging warehouses on its premises. This time, we toured the second warehouse, which houses rack-style storage.

Warehouse One, covered in grass

|

|

The Second Warehouse currently stores approximately 2,000 barrels of raw spirit.

Despite being in Okinawa, the aging warehouse—with its stone-walled exterior and concrete floors and walls—remains pleasantly cool even in summer due to the high volume of liquids stored.

There, awamori, Whisky, and rum age side by side in the same space, sharing the same maturation process.

The barrels lining the space are remarkably diverse.

Alongside staples like American white oak, bourbon barrels, and sherry casks, there were also cognac barrels and, notably, large Limousin oak barrels prepared for the “100-Year-Old sake Project” – barrels rarely seen elsewhere.

This is a sight unique to Helios Distillery, which handles multiple spirits, and the distillery itself feels packed with the essence of the Kyoda Distillery.

Custom-made Limousin oak barrels for the 100-Year Aged Awamori Project, started in 2000. Aging continues until 2100.

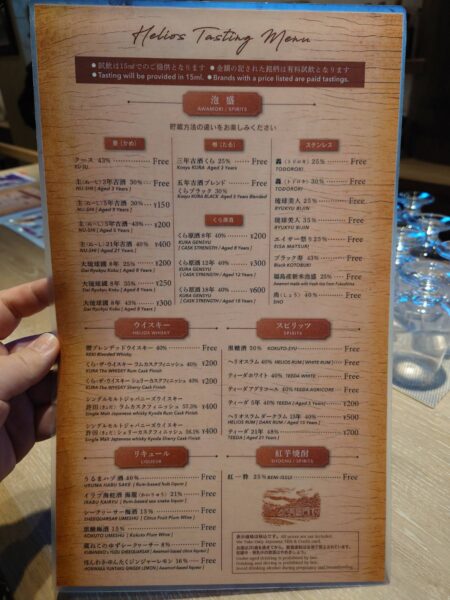

Shop Information

The attached shop offers an exceptionally well-stocked selection of merchandise.

It features exhibits detailing Helios Shuzo’s history and miniature models of distillery equipment. Even without a distillery tour, it’s a space where you can thoroughly enjoy yourself, including tastings.

Inside the shop, you can purchase and sample distillery-exclusive whiskys, awamori, and long-aged Helios rum.

Furthermore, rare Okinawa spirits like habu snake wine and sea snake wine are also available, allowing visitors to experience the breadth of the local drinking culture just by stopping by.

|

|

|

|

|

|

Summary

Okinawa is one of Japan’s premier resort destinations, yet it is also a place with unique culture and climate.

High temperatures and humidity, drastic temperature fluctuations, and accelerated maturation.

Throughout the production process, we observed the judgment and ingenuity that transformed these elements—which are rarely encountered domestically and are inherently challenging to work with—into distinctive characteristics of the sake.

Embracing the new while cherishing the old. This flexible approach pursues “sake born only here.” It is precisely this stance that creates the unique character of the ‘Kyoda Distillery’.